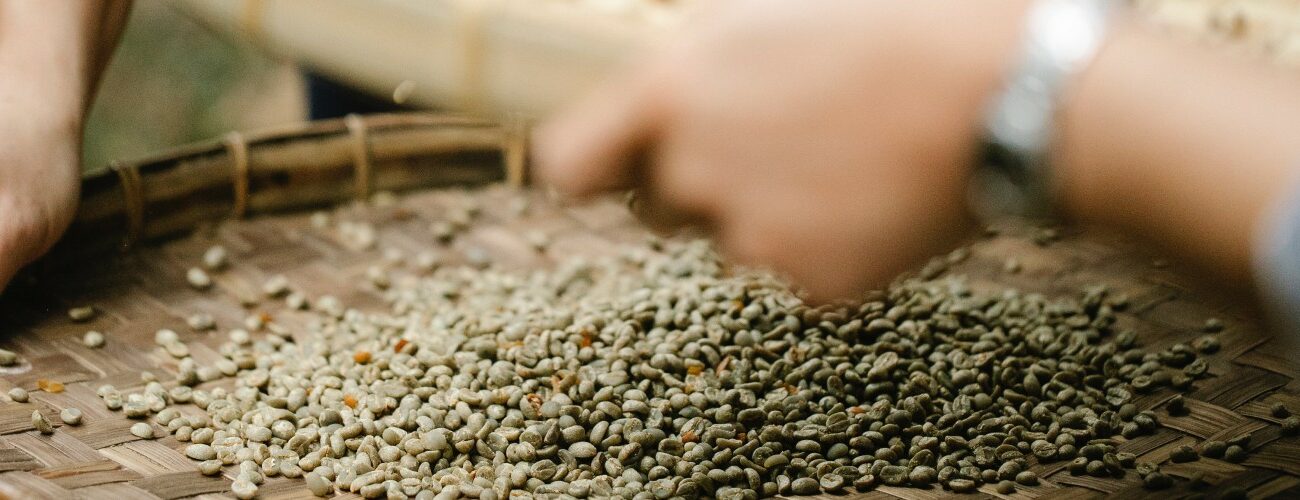

Coffee bean processing methods is an important step in the journey from farm to cup. The processing method used can have a significant impact on the flavour, aroma, and overall quality of the coffee. In this article, we will discuss five popular coffee processing methods.

1. Natural Process

The Natural Process, also known as the Dry Process, is a coffee bean processing method that involves drying the whole coffee cherry in the sun, allowing the coffee beans to absorb some of the fruit’s sweetness and flavor. The coffee cherries are spread out on raised beds or patios in the sun for several weeks until they are completely dried. During this time, the cherries are turned regularly to ensure even drying and to prevent mold and fermentation.

Once the cherries are fully dried, they are hulled to remove the outer layer of skin and parchment, revealing the green coffee beans inside. The natural process is the oldest and most traditional method of coffee processing, and it is still used in many coffee-growing regions around the world.

The Flavour

The natural process produces coffee with a full, heavy body and a sweet, fruity flavour. The acidity is typically lower than in washed coffees, and the flavour profile can vary widely depending on the specific growing region and the variety of coffee. Natural process coffees can be particularly complex and nuanced, with notes of berries, stone fruit, chocolate, and spices.

However, because the coffee cherries are dried with their fruit still intact, natural process coffees can also be more susceptible to defects and flavours if not carefully monitored and processed. As a result, the natural process is often considered more challenging and risky than other processing methods.

2. Washed Process

The Washed Process is a coffee bean processing method that involves removing the outer layers of the coffee cherry before drying the beans. The process begins by pulping the cherries using a machine to remove the skin and fruit. The beans are then washed and sorted by weight, with heavier beans indicating higher quality.

After washing, the beans are fermented in water for a period of time to remove any remaining fruit or mucilage. The length of fermentation can vary depending on the desired flavour profile, but it is usually between 12-36 hours. After fermentation, the beans are washed again to remove any remaining residue and then dried on raised beds or patios.

The Flavour

The washed process produces coffee with a bright, clean flavour and a well-defined acidity. Because the fruit and mucilage are removed before drying, the beans have a consistent flavour profile and are less likely to develop off-flavors or defects. Washed process coffees are often described as having a floral or citrusy aroma, with flavours of berries, chocolate, or nuts.

However, the washed process requires a lot of water, which can be a challenge in areas with limited water resources. It is also a more time-consuming and expensive process than the natural process, as it requires more equipment and labor. Despite these challenges, the washed process is widely used in many coffee-growing regions around the world and is known for producing high-quality specialty coffees.

3. Semi-Washed Process

The semi-washed process, also known as the wet-hulled process, is commonly used in Indonesia and other parts of Southeast Asia. It involves removing the skin and pulp from the coffee cherry using a pulper, but the beans are then dried with some of the mucilage still attached. The parchment is then removed from the beans while they are still moist, before they are fully dried.

The Flavour

The semi-washed process produces coffee with a medium body and a balanced flavor profile. The flavor can vary depending on the amount of mucilage left on the beans, but semi-washed coffees are often described as having a sweetness and a mild acidity. The flavor profile may include notes of fruit, chocolate, or caramel.

The semi-washed process is less risky than the natural process, as the coffee beans are less susceptible to defects and off-flavors. However, it still requires careful monitoring and attention to detail to produce high-quality coffee. The semi-washed process is particularly popular in Brazil, where it is known as the “Pulped Natural” process.

4. Honey Process

The honey process, also known as the pulped natural process, is a hybrid of the washed and natural processes. It involves removing the skin and pulp from the coffee cherry using a pulper, leaving some of the fruit’s mucilage attached to the beans. The beans are then dried with the mucilage still intact.

The Flavour

The honey process produces coffee with a medium body and a balanced flavor profile, with notes of fruit, nuts, and chocolate. The flavor profile can vary widely depending on the amount of mucilage left on the beans and the specific growing region. Honey process coffees are often described as having a sweetness and a mild acidity.

The honey process is a relatively new method of coffee processing, and it is becoming increasingly popular among specialty coffee roasters and consumers. It requires careful monitoring and attention to detail to produce high-quality coffee, but it offers a unique and complex flavor profile that is highly sought after by coffee enthusiasts.

5. Carbonic Maceration Process

The Carbonic Maceration Process is a coffee bean processing method that is relatively new and experimental, and it is becoming increasingly popular among specialty coffee producers. The process involves fermenting the coffee cherries in an oxygen-free environment, which allows the beans to absorb more of the fruit’s natural sugars and flavors.

To begin the process, the coffee cherries are sorted and placed in a sealed container that is filled with carbon dioxide gas. The cherries begin to ferment naturally, with the carbon dioxide gas helping to maintain a consistent temperature and prevent oxidation. The cherries are left to ferment for a period of time, usually between 12-48 hours, depending on the desired flavor profile.

After fermentation, the cherries are removed from the container and dried on raised beds or patios in the sun. The drying process can take several weeks, and the beans are turned regularly to ensure even drying and to prevent mold and fermentation.

The Flavour

The carbonic maceration process produces coffee with a unique and complex flavor profile that is often described as fruity, floral, and wine-like. The flavor profile can vary widely depending on the specific growing region and the fermentation time and temperature. Carbonic maceration coffees are often highly sought after by specialty coffee roasters and consumers, as they offer a distinct and memorable taste experience.

However, the carbonic maceration process is more time-consuming and expensive than other processing methods, and it requires specialised equipment and expertise. As a result, carbonic maceration coffees are typically more expensive than other specialty coffees.

Conclusion

In conclusion, coffee bean processing methods plays a crucial role in determining the flavour and aroma of coffee. The method used can change the coffee’s body, acidity, sweetness, and flavour profile. By understanding the different processing methods available, coffee lovers can choose the perfect cup to suit their taste preferences.